General Air Pump Inspection Guide:

- Remove plastic air filter cover.

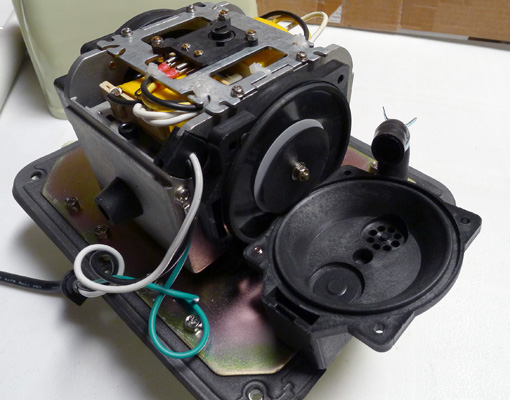

- Flip pump up side down and unscrew 6 screws on the corners and long side of the pump.

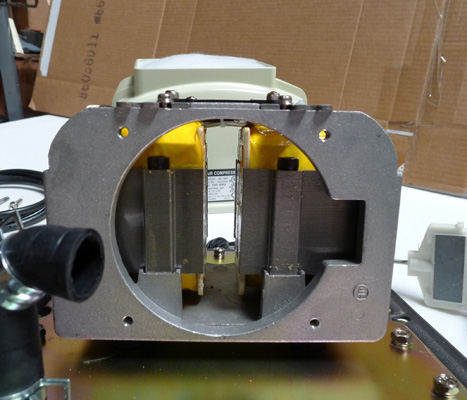

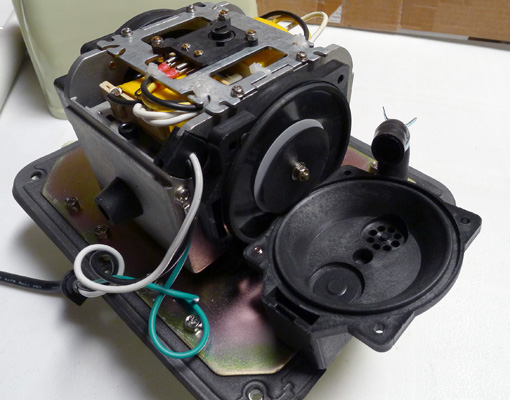

Flip pump over and proceed to lift upper housing.

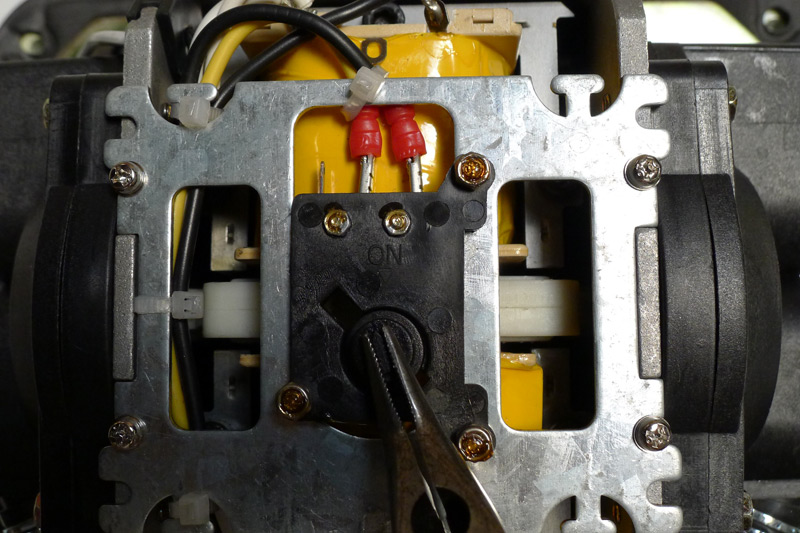

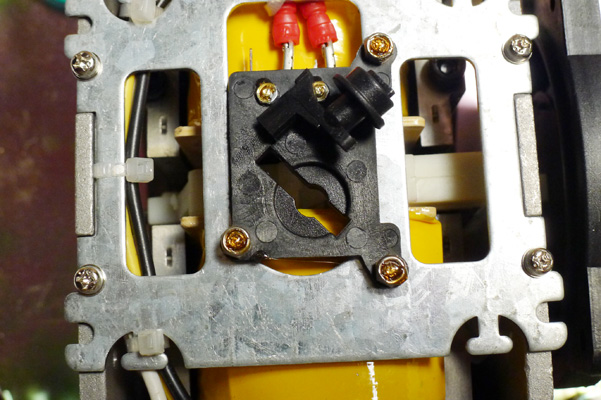

- Rotate and slide out of the detection pin knob on top of the pump core.. This move the detection pin out of way when you are pulling the magnetic bar out of the pump.

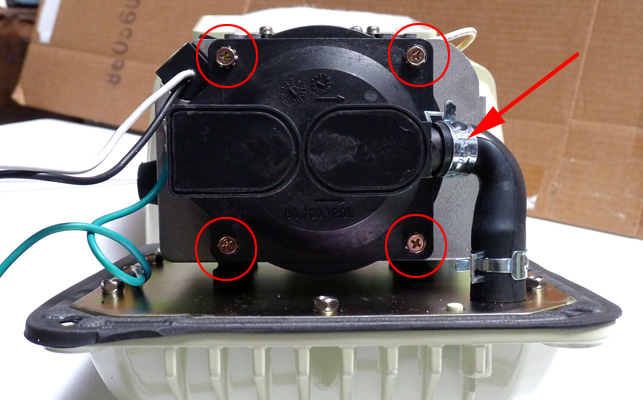

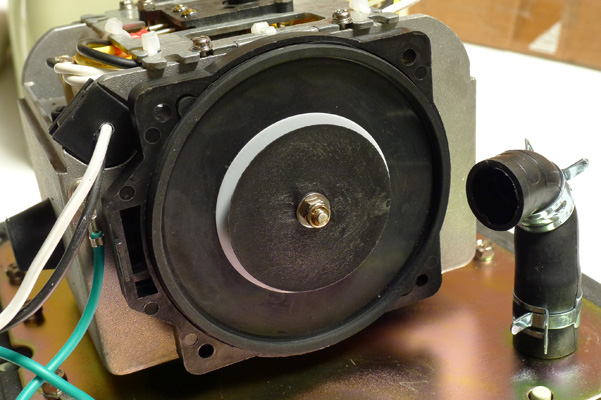

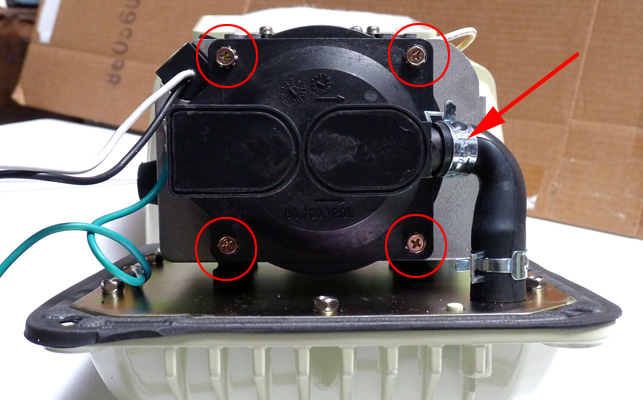

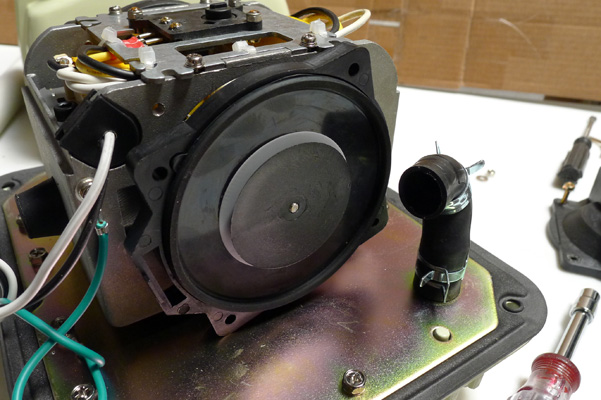

- Pick any side, unscrew the 4 corner screws that secure the diaphragm housing to the pump's core frame.

For AL-150/200, ignore all the screws not at the 4 corners.

- (See pointing arrow in #4) Unclamp and pull the rubber elbow away from the discharge port of the diaprhagm housing.

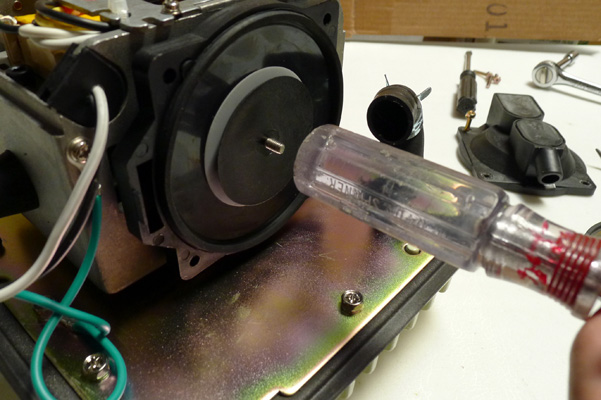

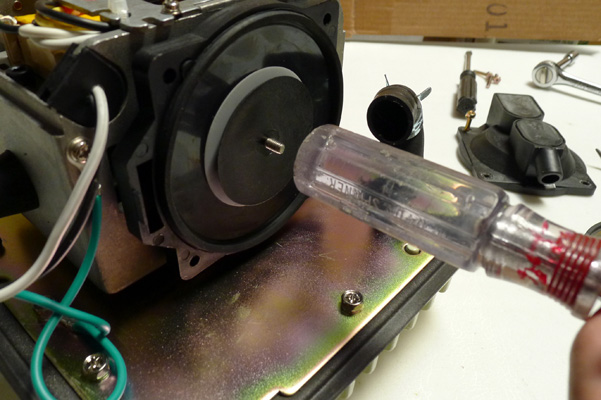

Carefully use a small flat bladed screw driver to unbond / uncouple the rubber tube from the discharge port then pull it away.

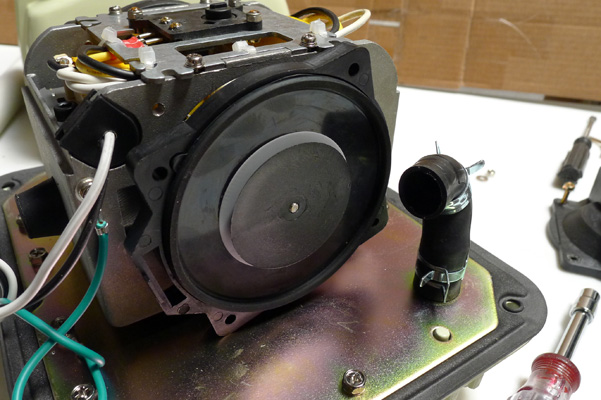

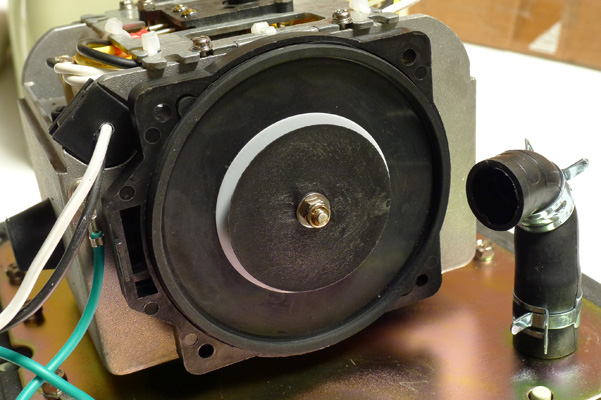

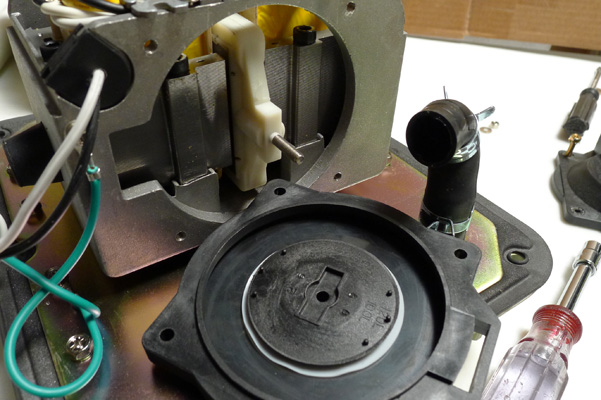

- Next pull the diaphragm housing away.

- Unscrew the hex nut at the center of the diaphragm and proceed to pull the diaphragm from the magnetic bar.

- If it is difficult to pull the diaphragm from the magnetic bar, use the handle of the screw driver as a hammer and nail down the protruded rod screw of the magnetic bar from the diaphagm plate.

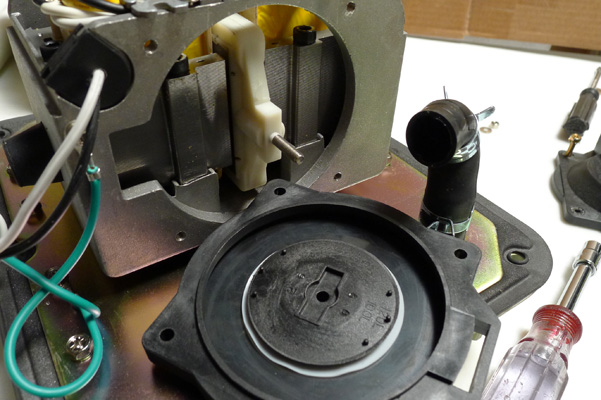

- Repeat #5 and #6 on this guide for the diaphragm module on the other side of pump. Then grab on the diaphragm frame than slide and pull the magnetic bar from pump core.

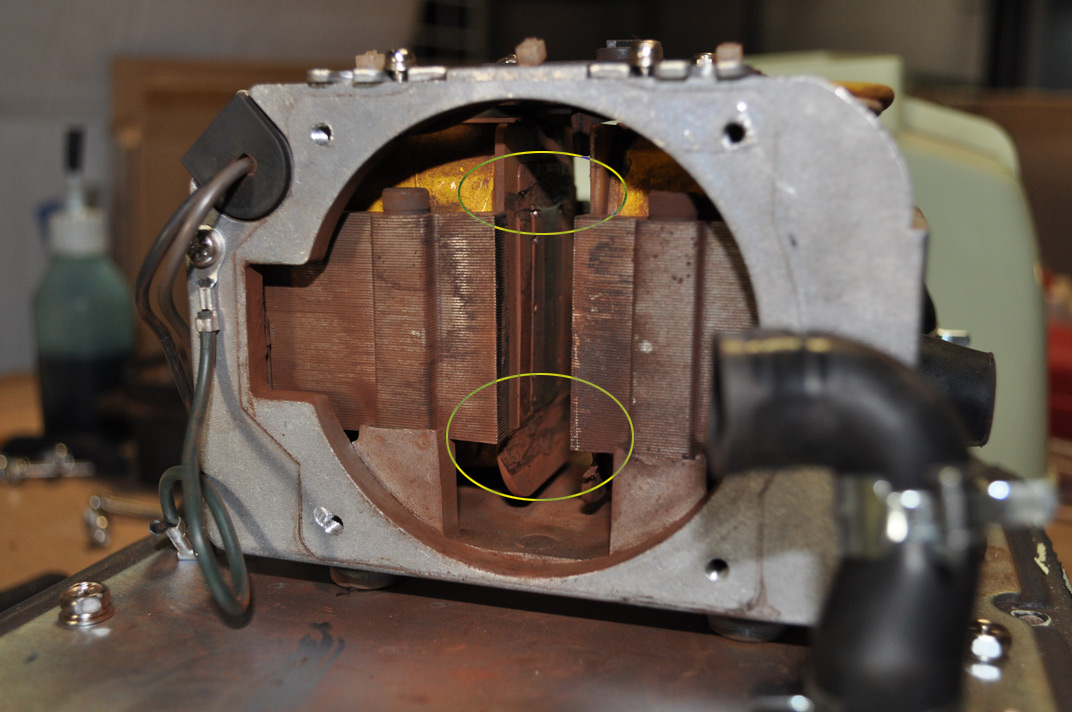

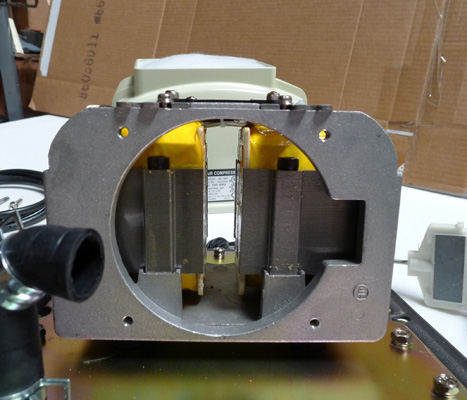

- Proceed to inspect any damage to the magnetic bar.

If there magnetic bar is fine, just order the diaphragm replacement kit.

If the magnetic bar is bent or the frame is cracked, it has to be replaced.

Scratch on the surface is fine as long as the magnets are not crack or become loose.

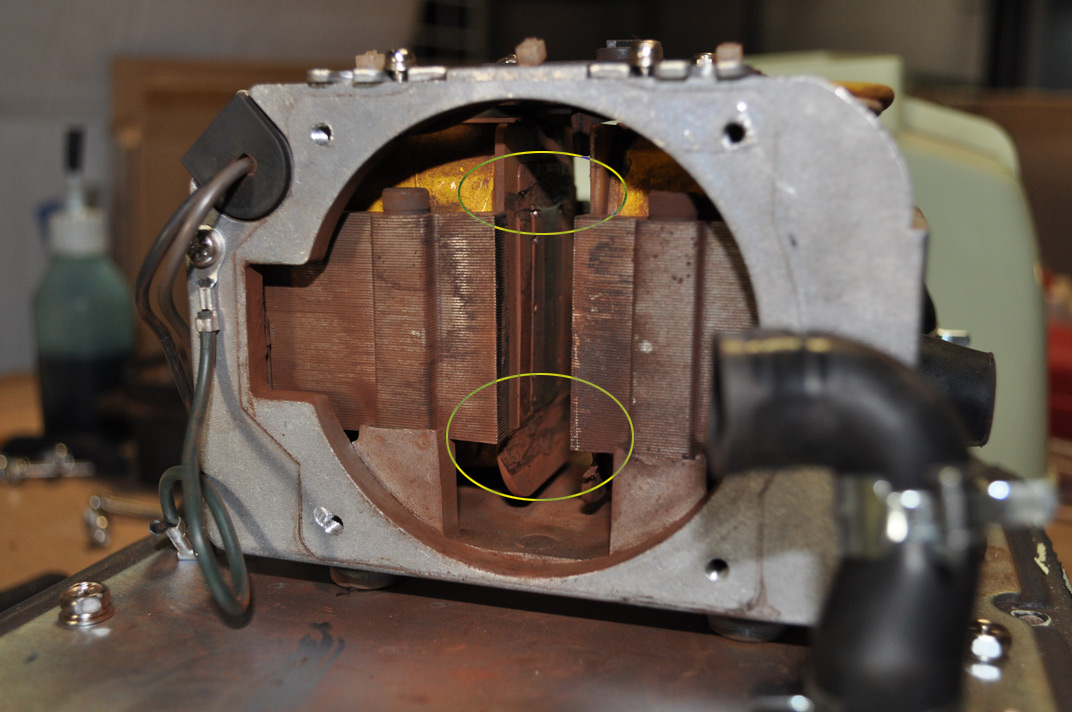

Here is a magnetic bar that is bent and require replacement.

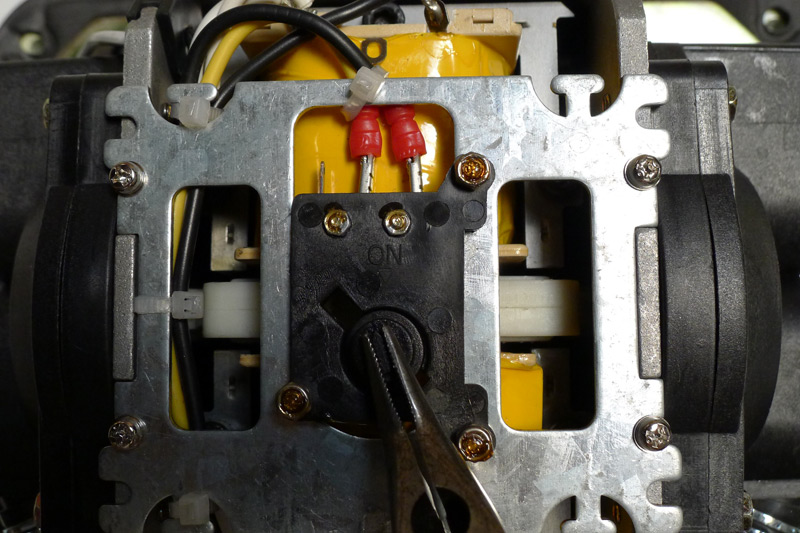

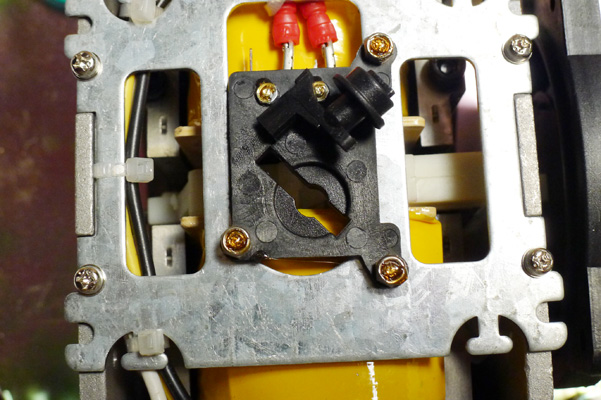

- Next inspect the electromagnets for any damages (coil winding).

- Scratch on the surfaces of the plastic insulator frame is okay, as long as the copper windings are not exposed.

- If the copper coil winding is exposed, if it is not scratched at all, it will still be okay.

However, if winding is scratched or burnt (black), then a new pump is required or the pump needs to be sent in for major overhaul.

If there are any copper pallets anywhere in the pump, the electromagnets are damaged.